This MF series of Ceramic Muffle Furnace is a periodic operation type, for laboratories, industrial and mining enterprises, scientific research institutions, colleges and universities for sintering of metal materials, ceramic materials, heat treatment of some single crystals, high temperature reburning shrinkage of refractory materials and general small steel parts quenching, annealing, tempering and other heat treatment heating.

Characteristics:

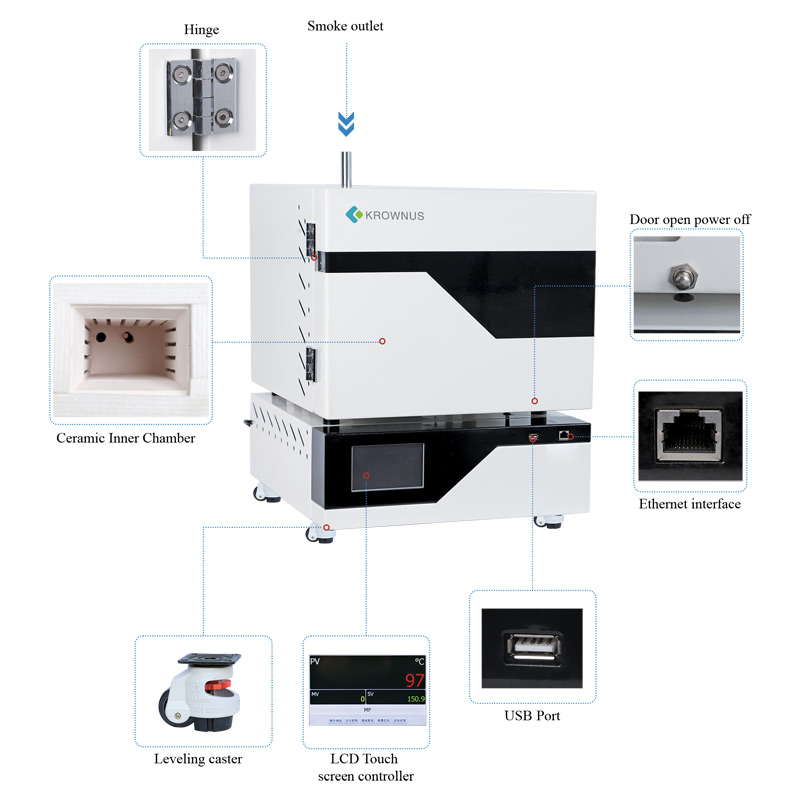

1.The inner chamber of furnace is made of ceramic fiber material, which has the characteristics of light weight, small hot melt and small heat loss in empty furnace.

2.The heating speed is fast, and it only takes 15 to 20 minutes to rise to 1200°C.

3.The two working modes of fixed value and program can be switched.

4.In program mode, there are 30 program segments and multiple sets of recipes.

5.Unique housing thermal duct design, to ensure that the outer temperature is low, not hot.

6.Side open door structure, open flexible and convenient, hidden door lock, beautiful appearance.

7.The furnace door switch detector is provided. After the furnace door is opened, the heating will be automatically cut off to protect the operator’s safety.

8.High-performance 5-inch HD LCD touch temperature controller, using AI artificial intelligence algorithm to ensure accurate temperature control effect.

9.Displays real-time trends, light columns and historical curves.

10.With USB interface, historical data can be exported to the computer for analysis and viewing.

11. With Ethernet interface, It can be use APP to remotely monitor and operate the instrument.

12.Using high quality SSR as temperature control element, no noise, long life, not easy to damage.